Baton Rouge Born. Gulf Coast Grown.

When supply chains are stressed, last-mile delivery tends to dominate the conversation. But for manufacturers, distributors, and logistics planners, the real pressure often starts when goods move from ports or production sites into staging and storage.

This upstream movement is where disruptions can multiply. Port congestion, labor gaps, and transportation volatility often destabilizes even the most efficient operation. And the downstream impact? Missed handoffs, costly delays, and reduced visibility.

As pressure mounts, companies are reassessing how they position inventory–not just where it’s stored, but who they trust to help them stay agile.

Proximity Without the Pressure

Proximity to major ports remains essential, but crowding these logistics hubs can introduce friction: bottlenecks, storage constraints, and rising operational costs.

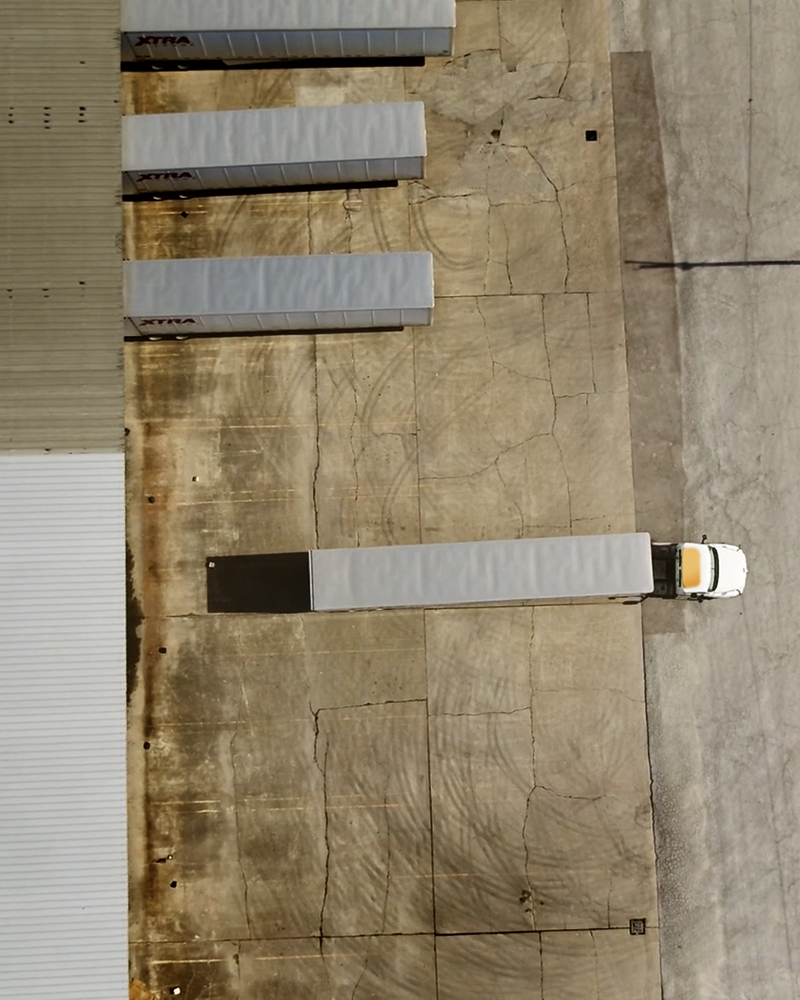

In response, many companies are shifting inventory just outside core business centers, close to highways and rail, but far enough to avoid congestion. Locations along the I-10 corridor have emerged as strategic alternatives, especially for companies balancing scale with speed.

Warehousing near the I-10 corridor helps reduce reliance on congested infrastructure while keeping goods close to key markets. For many companies, it’s a strategic lever for balancing responsiveness and cost efficiency.

Flexibility That Moves with Demand

Static service agreements often struggle to keep up with fluctuations in demand or shifting operational priorities. Today, more businesses are looking for partners who can scale with them. That might mean expanding space for a seasonal surge, coordinating short-haul trucking and port drayage, or integrating on-site services like repackaging and redistribution. Reducing handoffs across these services keeps freight moving, even when demand pivots overnight.

Adaptability is no longer a value-add. It’s a baseline requirement for supply-chain customers.

Built for What Comes Next

For industrial and B2B companies, regional logistics strategy is no longer just about square footage. It’s about adaptability and foresight.

By shifting inventory to flexible, regionally placed facilities, companies gain control, reduce risk, and build resilience into the system. This approach is especially valuable when the next disruption is a matter of “when,” not “if.”

That’s why companies are turning to logistics providers with experience navigating the I-10 corridor and Gulf Coast region. With longstanding relationships and integrated services, the Wilson Warehouse family of brands helps clients stay ahead of disruption without sacrificing efficiency.

At Wilson Warehouse, our regional footprint isn’t just about location—it’s about building resilience into your supply chain, no matter what comes next.

Let’s explore how a regional approach could strengthen your next move.